Service Professions

Control

Optimized checks based on the typologie of the diverse products

Here at Servica, each product is different, we have to constantly adapt our production rates to the typologie of the various products. Every step of the checks are formalized on the order of the manifacture (filing for 10 years). Each default detected during the final check up must undergo an intern non compliance.

Crimping checks with Komax Alpha Robot

Comprehensive list of controls

Post reception componant check up :

- Audit of quantities, references, expiry date...

Cut checks

- Corespondance plan check/ FO nomenclature and index

- Total length after instruction check

- Color, length and strip check

- Marking check

- Labeling check (readibility and cleaningless)

- No cuted strand check

- Cutting aspect check : straight cut

- FO quantity and machine check

- Wire aspect check (scrapes, marks)

Crimping checks

Visual compling check (check any deformation of the terminal Taring resistance check (crash test) Dimensionnal check (measuring of the heigh and width of the crimping) Automatic check on the crimping press (in production) Calibration check (enable the mac

Benchmark test for functionnal check

Compacting check (enablement of the tools)

- Respected crimping height

- Filling rate superior to 85%

- «Cats ears», less than half the thickeness of the terminal

- Heart and closed crimping

- Prohibited cracks

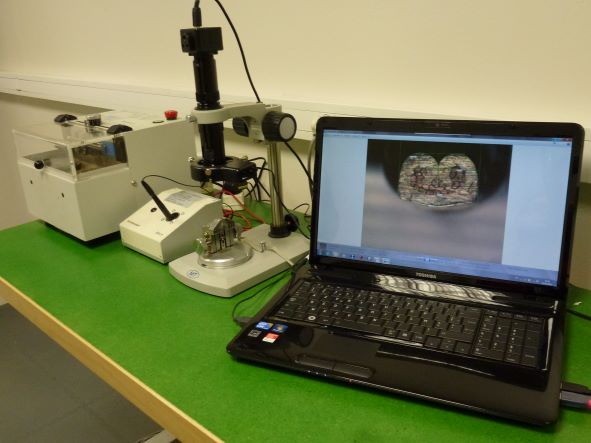

Crimping compacting in KOMAX SBL MICRO 3 analysis laboratory.

Final checks

- Visual

- Bell

- Electric testing (contuinity and short circuiting), with Cirris and CableEye testors

- Fonctionnal tests with a client process