Service Professions

Compacting

Crimping compaction analysis | Servica

Analysis aimed at assessing the condition of the crimping tools, before they are put into service and then periodically.

Crimping Tool

The basis of a good crimping begins with a compaction analysis

Upon the arrival of a crimping tool, we conduct a compaction analysis to validate compliance.

Compaction will be performed periodically throughout the life of the tool, depending on the number of crimp connector or a crimping defect found.

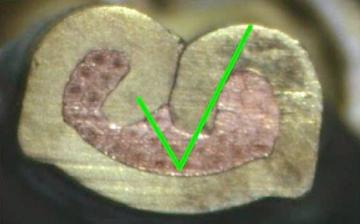

Valid compacting

The steps of a compacting analysis

- Crimping a lug

- Cutting at the crimp barrel

- Polishing

- Cleaning by electrolysis

- Calculation data by a microscope coupled to a computer

Compacting default

Our requirements are

- Respected crimp height

- Filling rate greater than 85%

- "Cat's ears" of less than half of the thickness of the terminal

- Crimping heart and closed

- Cracks are prohibited